Reduction of carbon footprint through compressed air

Hello there, how do you reduce your Carbon footprint in your industrial plant….?

Is there is a link between energy consumption and CO₂ emission?. YES, there is, undoubtably!

While using more energy, electricity companies need to produce more energy. A vast percentage of this electric energy is produced in power stations still are using gas, coal, or any other fossil fuels. This leads directly to CO₂ emissions. That means the consumer of electricity is solely responsible for the CO₂ emission that is produced.

This is something we all now already. That means if we reduce our energy consumption, we reduce the emission of CO₂. That is obvious.

What less people know is that compressed air is a form of energy that requires a lot of power to be produced. The industry uses it as a safe and reliable utility. But being it a utility that has less than 50% energy efficiency it is both an awfully expensive utility and has an impact on CO₂ emission as explained earlier.

So, reduce your compressed air consumption and be critical about your process that is using compressed air. Here are some facts.

Every compressed air system has leaks! In the most perfect air system, the leakages are less than 5%. Unfortunately, most systems where leaking detection has never been done and there is no focus on, leakage can be between 10% and 25% of the total air production.

Is it that bad? YES, it is. Detection and repair of leaks instantly saves your money and will reduce your CO₂ emission. Apart from that, the higher the energy prices are, the more you will save by starting to survey your system leaks.

Many companies still believe that more pressure is better. Well, I am convinced that a lot of companies will still run efficiently on a lower system pressure than they do today. It is a fact that 1 bar of pressure rise will cost 14% extra energy to produce. The reason that companies produce higher pressure can, in many cases, be found in the downstream system. That means if you suffer pressure drop in your system, you need to produce a higher pressure to have enough at the end of the line. Sometimes systems are old, and production has been increasing over the years. In those cases, it is a clever idea to upgrade your compressed air system with an oversized and lower pressure drop system. ROI will be better than you would ever have imagined.

What else can be done?

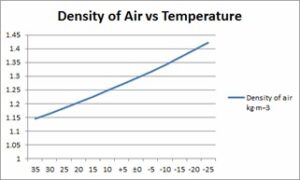

Well some time ago, I wrote an article about the negative effect of high ambient temperatures in your compressor room ( READ HERE ). Make sure you have fresh air of the lowest possible temperature at the suction side of your compressor. Because colder air is more dens, the absorbed power to produce compressed air at a certain pressure is less than for warm (thinner) air. Enough examples were up to 5% can be gained in reducing energy consumption.

Talking about overheating. The same counts for compressors running on higher temperatures due to lack or inefficient maintenance. Make sure you periodically clean and maintain your compressor installation. It will lower the temperature and will reduce energy cost.

So, pick the low hanging fruit without huge investments by;

- Reducing your compressed air consumption

- Performing a leak detection survey and repairing the leaks

- Lowering your system pressure by lowering the compressor setpoint

- Evaluate your compressed air piping and replace where needed

- Lowering the compressor room temperature as much as possible

Tackling your compressed air system opportunities is lowering energy consumption is reducing your carbon footprint.